the raw slab

Making progress on bark removal

Making progress on bark removal

Bark all removed

preparing for the epoxy pour to fill in cracks and holes

The raw slab

How the epoxy pour started

How it ended, after the hotdog cut

All clean after a few passes in the planer

The feet cut off

preparing to cut the grooves for the air stitching

Action shot of the router carving the grooves

all grooves cut

test fit of the walnut

all stitched up

dry assembly

dry assembly

Legs attached securely in place, getting ready for the finish

Legs attached securely in place, getting ready for the finish

Legs attached securely in place, getting ready for the finish

Legs attached securely in place, getting ready for the finish

Legs attached securely in place, getting ready for the finish

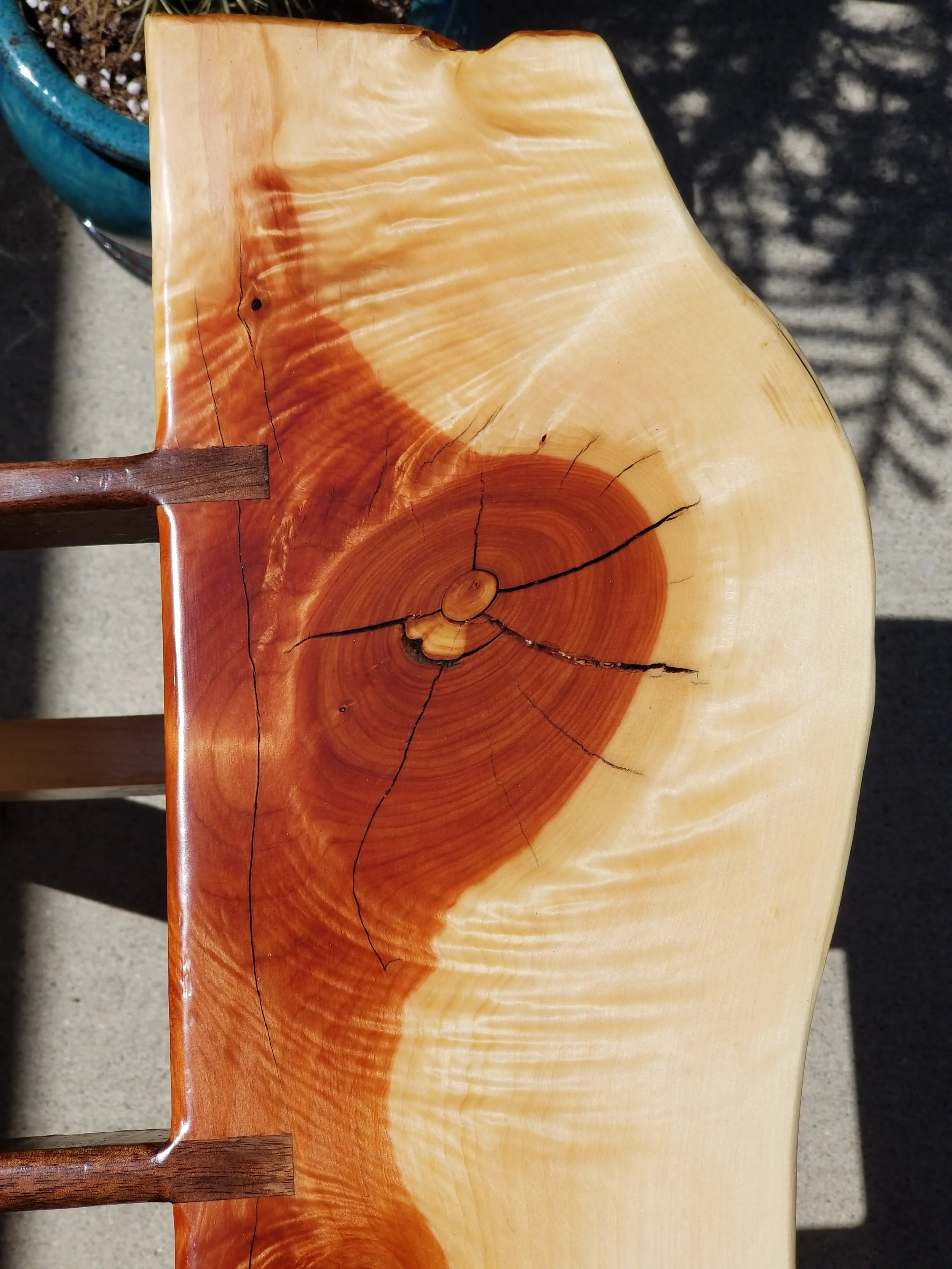

First coat of epoxy

after a few coats

how I coated the underside and legs